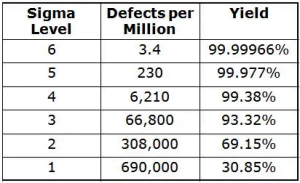

Six Sigma is a data-driven methodology used to improve business processes and reduce variation. It aims to achieve near-perfect quality by identifying and eliminating defects or errors. The term “Six Sigma” refers to the statistical concept of six standard deviations between the mean and the nearest specification limit. By applying the principles and tools of Six Sigma, organizations can improve processes, reduce costs, enhance customer satisfaction, and achieve sustainable business growth.

Lean + 6σ = Lean 6σ

Lean (e.g. KAIZEN)

Improve process through the reduction or eliminiation of waste. Focus: Waste elimination and supporting quality process

6σ (Six Sigma)

Improve process through the reduction of variation. Focus: Reducing the variation in quality and supporting speed.

KAIZEN is a key concept in Lean methodology. It refers to the continuous improvement of processes, products, and services in order to achieve greater efficiency and effectiveness.

The word “KAIZEN” comes from the Japanese words “KAI” (change) and “ZEN” (good), which together mean “change for the better” or “continuous improvement.” In Lean, KAIZEN focuses on eliminating waste and streamlining operations by making small, incremental changes.

It encourages every employee, from the front-line workers to the management team, to identify opportunities for improvement and implement solutions. KAIZEN promotes a culture of continuous learning, innovation, and teamwork. By embracing the KAIZEN philosophy, organizations can achieve continuous improvement, increase productivity, reduce costs, enhance quality, and ultimately create more value for customers.

Key Principles and Practices of KAIZEN in Lean

- GEMBA: Going to the actual place where work is done to observe and understand the current state of processes.

- Muda, Mura, Muri: Identifying and eliminating the three types of waste: Muda (non-value-added activities), Mura (unevenness or variability), and Muri (overburden or strain).

- 5S Methodology: Implementing the 5S methodology to create a clean, organized, and efficient workspace. The 5S principles are Sort, Set in Order, Shine, Standardize, and Sustain.

- Standard Work: Establishing standardized processes and work instructions to ensure consistency and reliability in operations.

- Visual Management: Using visual cues, such as signs, labels, and charts, to communicate information clearly and facilitate understanding.

- KAIZEN Workshops: Organizing focused, time-bound improvement projects where cross-functional teams work together to address specific challenges and implement solutions.

The Origin Of 6σ

- Sigma is the 18th letter (uppercase Σ, lowercase σ) of the Greek alphabet and is equivalent to our letter ‘S‘ or ‘s‘ respectively.

- Mathematics -> The (uppercase) Σ is a symbol for sum or signature or simply sum up -> Sigma Notation.

- Measurement-> Speed of star movement at the outermost edge of a galaxy (approx. 100 km/s or 360000 km/h)

- Type of Man -> A Sigma Male refers to a certain type of man (very rare: 0.1%) who stands out due to his strength, intelligence and independence. He is above an Alpha Male and a self-confident but also introverted man.

- Six Sigma comes from the Bell Curve Used In Statistics, where one Sigma (lowercase σ) symbolizes a single Standard Deviation from the mean. If the process has six Sigmas (3 above and 3 below the mean), the defect rate is classified as “extremely low.”

In the early 1980’s Bill Smith at Motorola developed Six Sigma principles in order to measure defects and improve overall quality. GE then first and widely applied these principles in its daily operations largely under the direction of Jack Welch

6σ Principles & Doctrine

The core principle of Six Sigma is to identify and eliminate defects in processes, products, or services by using statistical analysis and data-driven decision-making

- Always focus on the customer

- Understand how work really happens

- Make your processes flow smoothly

- Reduce waste and concentrate on value

- Stop defects through removing variation

- Involve and equip people in the process

- Make your efforts systematic and scientific

Six Sigma is based on three key ideas that comprise the Six Sigma doctrine

- Continuous efforts to achieve stable and predictable process results (i.e., reduce process variation) are of vital importance to business success.

- Manufacturing and business processes have characteristics that can be measured, analyzed, controlled and improved.

- Achieving sustained quality improvement requires commitment from the entire organization, particularly from top-level management.

The 6σ Methodologies

Six Sigma projects follow two project methodologies, inspired by W. Edwards Deming’s PDCA, each with five phases.

- DMAIC is used for projects aimed at improving an existing business process

- DMADV is used for projects aimed at creating new product or process designs

The DMAIC Model

- Define -> Project charter / Customer voice / Value-stream mapping / SIPOC

- Measure -> Process mapping / Process capability / Pareto chart

- Analyse -> Root cause analysis (Ishikawa diagram) / Failure mode & effects analysis / Multi-vari chart

- Improve -> Design of experiments / KAIZEN

- Control -> Control plan / Statistical process control / 5S / Poka-yoke

The DMADV Model

- Define design goals that are consistent with customer demands and the enterprise strategy.

- Measure and identify CTQs (characteristics that are Critical To Quality), measure product capabilities, production process capability, and measure risks.

- Analyze to develop and design alternatives

- Design an improved alternative, best suited per analysis in the previous step

- Verify the design, set up pilot runs, implement the production process and hand it over to the process owner(s).

6σ Belt Level Rankings

There are several (three main) tiers of official Six Sigma certification. Through training, an organization progresses to the next level of certification. Movement up the accreditation pipeline signals an organization’s proven mastery of Six Sigma concepts, as well as its ability to incorporate those concepts into daily workflows without reverting back to “old,” less efficient ways.

The 6σ Belt Levels

- Six Sigma White Belt: Professionals are considered Six Sigma White Belts if they have not undergone a formal certification program or extended training. A single session with an overview of relevant methods and vocabulary for LSS shows workers at all levels of an organization how they contribute to efficient, reliable outcomes. With this basic grounding, White Belts participate in projects and problem-solving tasks related to quality management and waste reduction.

- Six Sigma Yellow Belt: The Yellow Belt is the foundational tier of Six Sigma’s three methodologies. Yellow Belt training provides a topical overview of Six Sigma terms and applications, including managements’ roles, major statistical tools and typically the DMAIC model. Most importantly, the Yellow Belt Six Sigma certificate signifies an organization’s understanding of Root Cause Problem Solving, using appropriate data-gathering tools and techniques to reduce process variation.

- Six Sigma Green Belt: Six Sigma’s Green Belt is the intermediary accreditation available to manufacturing organizations. At this level, participants undergo in-depth tutorials on statistical tools and data modeling. Green Belt-certified professionals can select, initiate and analyze the exact statistical models best fit to solve a project or problem variation, fluent in proper data collection, calculations, representation, interpretation and, ultimately, control chart implementation.

- Six Sigma Black Belt: The Black Belt is the third and final tier of Six Sigma certification. It is the methodology’s most advanced accreditation. Industry professionals holding a Black Belt certificate are considered Six Sigma project leaders or managers, independently able to implement a Six Sigma template across an end-to-end process improvement. They are fluent in Six Sigma terminology, statistical tools and philosophical application and can coach and mentor team members at or below the Yellow and Green Belt levels.

- Master Black Belt: A seasoned Black Belt with strong leadership and problem-solving skills can go on to become a Master Black Belt in LSS. This designation indicates that an expert takes a broad view of strategy throughout a business, coordinating teams across

- Champion: A Champion is an upper-level manager who leads LSS strategy and deployment. Based on the objectives set by executive leadership, Champions ensure that all initiatives to lower waste and remove defects come together in alignment with a company’s needs for growth. Aided by Master Black Belts, these managers mentor the leaders involved in LSS implementation and track their progress.

The 6σ Black Belt

The Six Sigma Black Belt certification is a highly esteemed credential in the field of quality management and process improvement. To obtain this certification, individuals undergo rigorous training and demonstrate a thorough understanding of the Six Sigma methodology and tools. As a Six Sigma Black Belt, you are equipped with advanced knowledge and skills to lead and manage complex improvement projects within an organization. Your main responsibilities include:

Main Responsibilities

- Project Leadership: You take charge of leading improvement projects, setting project goals, and ensuring their successful completion.

- Statistical Analysis: You use statistical methods and tools to analyze data and identify areas for improvement.

- Process Improvement: You apply various Six Sigma techniques like DMAIC (Define, Measure, Analyze, Improve, Control) to identify and eliminate root causes of problems.

- Team Management: You lead and mentor project teams, guiding them through the improvement process and ensuring effective collaboration.

- Change Management: You help manage change within the organization by implementing strategies to facilitate smooth transitions and overcome resistance.

- Stakeholder Communication: You communicate progress, results, and recommendations to stakeholders at different levels of the organization.

By leveraging your knowledge and skills as a Six Sigma Black Belt, you contribute to achieving significant improvements in quality, efficiency, and customer satisfaction within your organization.

My 6σ Certification

These were the steps:

- Six Sigma White Belt

- Six Sigma Yellow Belt

- Siy Sigma Green Belt

- Six Sigma Black Belt

These were the ingredients:

- The Council for Six Sigma Certification

- “A complete step-by-step guide” (829 pages)

- “Black belt certification training manual” (557 pages)

- 21 various templates (MS Excel, MS PowerPoint, MS Word)

- 18 various tools (MS Excel, MS PowerPoint, MS Word)

- Minitab statistical software (you may use MS Excel instead)

What’s More

My Blog (59)

Dependence (5) Fiction (7) Karma (6) Landmarks (4) Paramount (6) Poignancy (5) Spectrum (6) Spotlight (5) Take Off (5) Unique (5) Virtue (5)

Amazing Stuff (9) Beyond Known (8) Controversial (10) Digital World (9) Endeavor Pursuits (2) Inequities (8) Innovative (8) Metaphysics (8) Our Society (9) Outer Space (9) Value Creation (9)