KAIZEN is a powerful practice in Lean Management that focuses on continuous improvement. It encourages small, incremental changes in processes, resulting in significant improvements over time. The word “KAIZEN” comes from two Japanese words: “KAI” meaning “improvement”, and “ZEN” meaning “good”.

KAIZEN – the power of enhancement through continuous small improvement steps – can be implemented in various sectors, including manufacturing and administration. It involves engaging all employees, from top-level executives to frontline workers, in suggesting and implementing improvements to the organization.

“There are no big problems – there are just a lot of little problems.”

– Henry Ford

Real-World Applications

KAIZEN has transformed industries worldwide, from manufacturing plants to corporate offices. In production, companies like Toyota have embedded KAIZEN into their workflow, where employees actively seek incremental improvements in processes—reducing waste, streamlining efficiency, and enhancing product quality. In service sectors, businesses use KAIZEN to refine customer experience by optimizing workflow, minimizing response time, and improving employee engagement.

Healthcare institutions have adopted KAIZEN methodologies to improve patient care, eliminate inefficiencies, and refine hospital management systems. Even education and software development benefit from KAIZEN principles, fostering adaptive learning methods and agile work environments.

Long-Term Benefits

KAIZEN is not just about short-term fixes – it fosters a culture of sustained improvement. Organizations committed to KAIZEN see enhanced productivity, heightened employee engagement, and continuous innovation. Small but consistent improvements prevent stagnation, allowing businesses to adapt to market changes dynamically.

Beyond measurable efficiencies, KAIZEN instills a mindset shift: Employees at all levels feel empowered to contribute ideas, strengthening teamwork and ownership over progress. Over time, companies with a KAIZEN-driven culture experience higher morale, reduced operational costs, and lasting competitive advantages.

Documents / Working Templates

Structured improvement efforts align priorities, surface issues early and drive effective, scalable solutions that strengthen performance and support sustainable operational practices.

The documents and templates in My Publications are part of Ninja Services trainings, helping participants apply Business Excellence initiatives effectively and secure lasting improvements.

The Dual Nature

KAIZEN has a dual nature, serving as both an Action Plan and a Philosophy. By embracing this duality, organizations can create a culture of continuous improvement where every employee actively contributes to making positive changes. This approach leads to increased productivity, improved quality, enhanced workplace safety, and a stronger organizational culture.

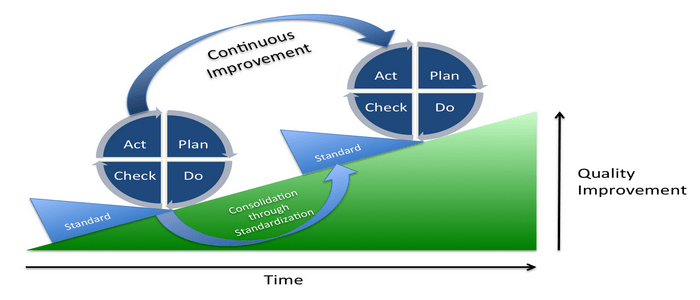

KAIZEN Action Plan

KAIZEN action plans involve events that focus on improving specific areas within a company, emphasizing the involvement of employees at all levels, especially plant floor workers. The process follows structured steps: setting goals, reviewing the current state, implementing improvements, addressing issues, and reporting results. A key tool in KAIZEN is the PDCA (Plan-Do-Check-Act) cycle, which takes a scientific approach to improvement by guiding goal-setting, current state evaluation, implementation, result assessment, and necessary adjustments.

A typical KAIZEN event goes something like this:

- Set goals and provide any necessary background.

- Review the current state and develop a plan for improvements.

- Implement improvements.

- Review and fix what doesn’t work.

- Report results and determine any follow-up items.

This type of cycle is frequently referred to as PDCA which brings a scientific approach to making improvements:

- Plan / Problem Finding (develop a hypothesis)

- Do / Display (run experiment)

- Check / Clear (evaluate results)

- Act / Acknowledge (refine your experiment; then start a new cycle)

KAIZEN Philosophy

KAIZEN is a philosophy aimed at fostering a culture of continuous improvement within organizations, encouraging all employees to actively suggest and implement enhancements. In truly lean companies, KAIZEN becomes second nature for both managers and workers. By consistently applying KAIZEN through action plans and sustained improvement events, organizations develop a culture of ongoing progress that supports long-term value. KAIZEN is not a one-time effort but a commitment to continuous improvement and building a proactive, collaborative workplace.

“Pull your finger out and leave your footprint.”

– Eric Roth

In addition to the PDCA cycle, there are various other tools available in the KAIZEN toolbox to achieve continuous improvement. These tools can help identify waste, optimize processes, and enhance overall efficiency. Examples of such tools include value stream mapping, 5S Methodology, root cause analysis, and Kanban.

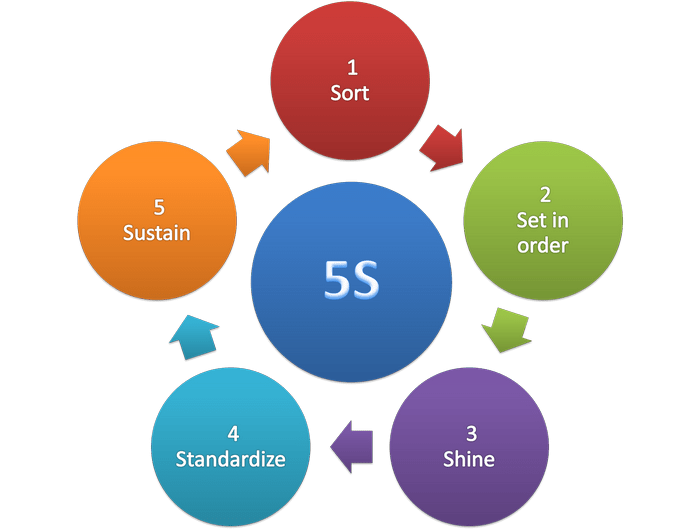

The 5S Methodology

The history of the 5S Methodology was most likely born from Toyota in Japan after World War II and has also been called TPS (Toyota Production System), the original JIT (Just-In-Time manufacturing).

However, some believe the method may origin back as far as the 16th Century and Venice shipbuilders. The 5S methodology as a today’s part of KAIZEN may therefore be a lot older than other sets of lean techniques and tools for process improvement such as Six Sigma.

By applying 5S consistently, organizations create a structured, efficient workplace that fosters productivity and innovation. This methodology enhances operations while strengthening employee engagement and a culture of improvement.

Each Of The 5S Explained

- Sort (seiri) – Distinguishing between necessary and unnecessary things, and getting rid of what you do not need.

- Remove items not used in area – outdated materials, broken equipment, redundant equipment, files on the computer, measurements which you no longer use.

- Ask staff to tag all items which they don’t think are needed – this improves understanding about need and use.

- Classify all equipment and materials by frequency of use to help decide if it should be removed – place ‘Red Tag’ on items to be removed.

- Establish a ‘holding area’ for items that are difficult to classify – hold item for allotted period to enable others not on 5S team to review.

- Straighten (seiton) – The practice of orderly storage so the right item can be picked efficiently (without waste) at the right time, easy to access for everyone. A place for everything and everything in its place.

- Identify and allocate a place for all the materials needed for your work.

- Assign fixed places and fixed quantity.

- Make it compact.

- Place heavy objects at a height where they are easy to pick from.

- Decide how things should be put away, and obey those rules.

- Shine (seiso) – Create a clean worksite without garbage, dirt and dust, so problems can be more easily identified (leaks, spills, excess, damage, etc).

- Identify root causes of dirtiness, and correct process.

- Only one work activity on a workspace at any given time.

- Keep tools and equipment clean and in top condition, ready for use at any time.

- Cleanliness should be a daily activity – at least 5 minutes per day.

- Use chart with signatures/initials shows that the action or review has taken place.

- Ensure proper lighting – it can be hard to see dirt and dust.

- Standardize (seiketsu) – Setting up standards for a neat, clean, workplace.

- Standardization of best practices through “visual management”.

- Make abnormalities visible to management.

- Keep each area consistent with one another.

- Standards make it easy to move workers into different areas.

- Create process of how to maintain the standard with defined roles and responsibilities.

- Make it easy for everyone to identify the state of normal or abnormal conditions – place photos on the walls, to provide visual reminder.

- Sustain (shitsuke) – Implementing behaviors and habits to maintain the established standards over the long term, and making the workplace organization the key to managing the process for success.

- Toughest phase is to Sustain – many fall short of this goal.

- Establish and maintain responsibilities – requires leader commitment to follow through.

- Every one sticks to the rules and makes it a habit.

- Participation of everyone in developing good habits and buy-in.

- Regular audits and reviews.

- Get to root cause of issues.

- Aim for higher 5S levels – continuous improvement.

Explore each of the 5S steps and discover how they transform everyday work by creating order, boosting efficiency and building the foundation for a culture of continuous improvement.

Ninja Services

Pragmatic, professional engagement rooted in global experience – Ninja Services to navigate complexity, optimize operations and generate results.

Eric’s Background includes well-developed, solid Core Competencies and he offers tailor-made solutions for both temporary assignments and permanent roles and is available for global travel on a flexible basis.

Contact Eric today for effective support in navigating challenges and driving success through Value Creation.

What’s More

The posts in My Blog feature reflective, story-driven pieces rooted in personal and societal insights.

The topics in My Interests explore abstract, philosophical ideas and their cultural and societal impact.

👁️ 10,200 Views